(Battery Grade Quartz)

Equity Metals Corp. is evaluating its leased silica sand deposit in central Saskatchewan for possible use in several industries, with potentially the most profitable use being in the rapidly evolving battery industry.

Chemical analyses show that material from the quarry can be upgraded to high-purity silica (98% SiO2 and greater) by simple washing to remove clay and organic material. This level of purity is required to produce Silicon, which is being investigated as an additive to lithium batteries that can greatly increase the amount of time batteries maintain a charge. Other users of high-purity silica include the ceramic and glass manufacturing industries.

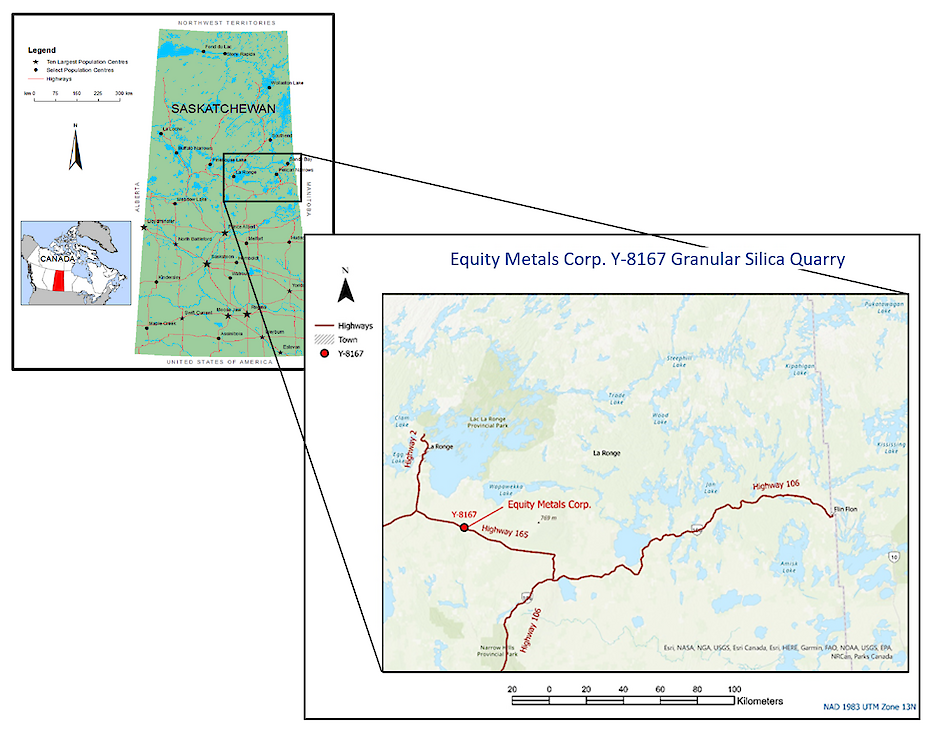

The sand is held by lease and is unconsolidated, simplifying a potential mining and washing operation. The lease includes exclusive rights to development and mining, subject to regulatory approvals. The lease is accessible by road from La Ronge, Saskatchewan, and Flin Flon, Manitoba, the nearest population centers.

Equity Metals Corp.’s granular silica sand quarry is located in central Saskatchewan, approximately 60 kilometers south-southeast from the town of La Ronge, Saskatchewan and 210 kilometers west of Flin Flon, Manitoba (See figure below).

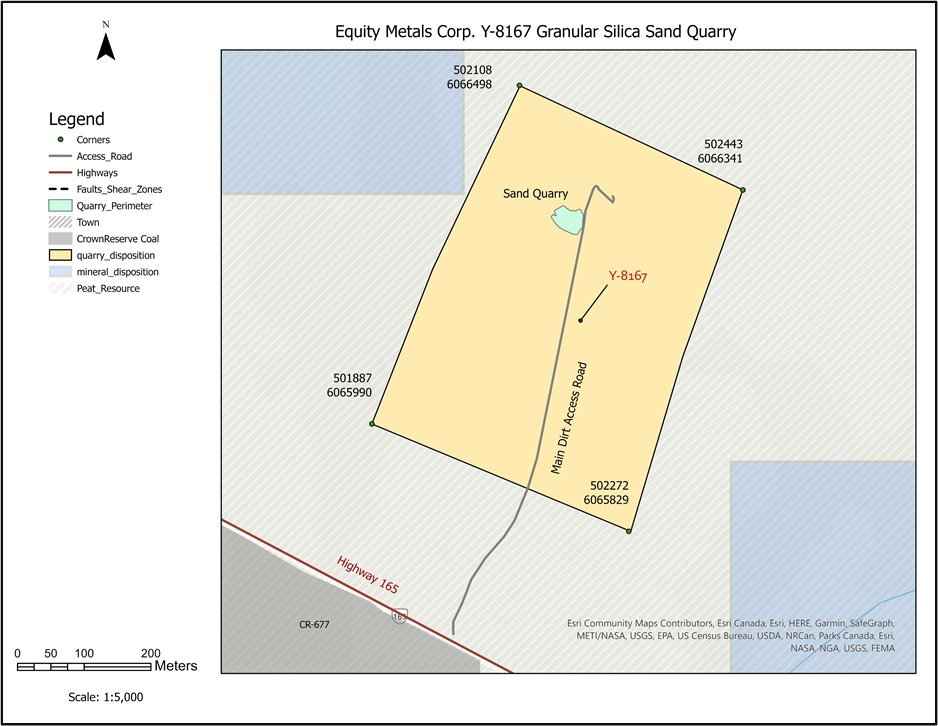

The quarry lease, Y-8167, was granted by the Resource Development, Ministry of Energy and Resources in the province of Saskatchewan to New Nadina Resources Inc. (now Equity Metals Corp.). The lease covers a rectangular area of approximately 21.85 hectares and has a term of successive five-year periods at an annual rental fee of $108. The sand quarry is located in the north-central portion of the lease. The current term expires December 10, 2024. The configuration of the lease is shown in the following diagram.

The sand quarry is located 500 meters north of Highway 165, a paved highway, an hour’s drive southeast of La Ronge. It is accessible by road from the highway. The sand is exposed in a quarry over an area of 50 meters long x 30 meters wide and to a depth of 6 meters. The ultimate dimensions of the deposit are presently unknown due to surrounding overburden and lack of drill testing. It is estimated that approximately 15,000 Tonnes of sand remain in the pit to the lowest elevation and would extend an additional 3,600 Tonnes per vertical meter to the ultimate bottom of the deposit. The sand is a semi-equigranular pure silica sand, particles ranging from fine to medium in size, and is described as being partly consolidated, breaking very easily when handled.

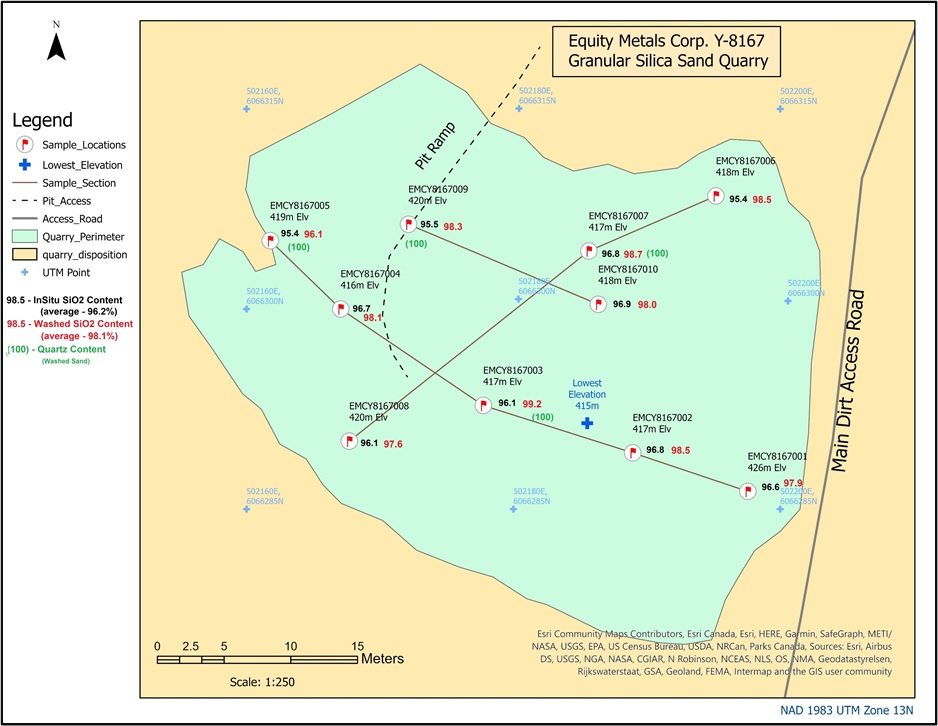

The sand quarry lease was granted initially to assist the oil and gas industry in fracking deep-seated and trapped oil and gas resources; however, as technology advanced and the need of sand lessened, New Nadina never mined the sand. Current management of Equity recognized the purity of the sand, and in 2021 initiated a sampling program to develop potential value of the deposit. 10 sample sites were selected, and sufficient sand samples were taken to derive average purity of the sand – see location of samples on the attached plan map of the quarry.

It is uncertain when mining initially occurred at the site, but it was believed to be in the 1980s or ‘90s, prior to ownership by New Nadina. Volume calculations indicate approximately 6,000 Tonnes were obtained and sold to the Oil and Gas industry.

The samples were initially analyzed by whole-rock analysis for SiO2, Al2O3, and other elements. Average results of 10 samples indicate 96.2% SiO 2 and over 2% Al2O3. It was assumed that much of the Al2O3 was in the form of clay that might be easily washed away, enriching the remaining silica sand. A process was developed to wash all 10 samples and to re-analyze the SiO2 and other elements by whole-rock analysis. The result was a range of residual SiO2 from 96.1 – 99.2% (average 98.1%) and less than 1% Al 2O3. The washing process lost a relatively minor percentage of the original samples, approximately 12% of the total sample (2% clay+LOI and 10% SiO2 lost). X-ray diffraction (XRD) has determined that 100% of the material identified by XRD is SiO2 in the form of quartz.

Specialty uses of high-purity silica include the manufacturing of pure silicon and use in glass manufacturing. Silicon is being tested by electric-car industry to replace or augment carbon in battery anodes to dramatically extend the time between charging.

Equity will investigate potential markets and partnerships to further advance this property.

John R. Kerr, P.Eng, BASc (geology), is a Director of Equity Metals Corporation and a Qualified Person as defined by National Instrument 43-101. He is responsible for the supervision of the exploration on the La Ronge Silica Sand project and approves the technical information in this disclosure.